Products

Indusenz INVENIO CUI Sensor System

Advanced Wireless Monitoring for Accurate CUI Prediction

Cutting-Edge INDUSENZ INVENIO CUI SENSOR SYSTEM Predicts Corrosion Under Insulation Events, Reducing Costs and Safety Risks in Industrial Applications.

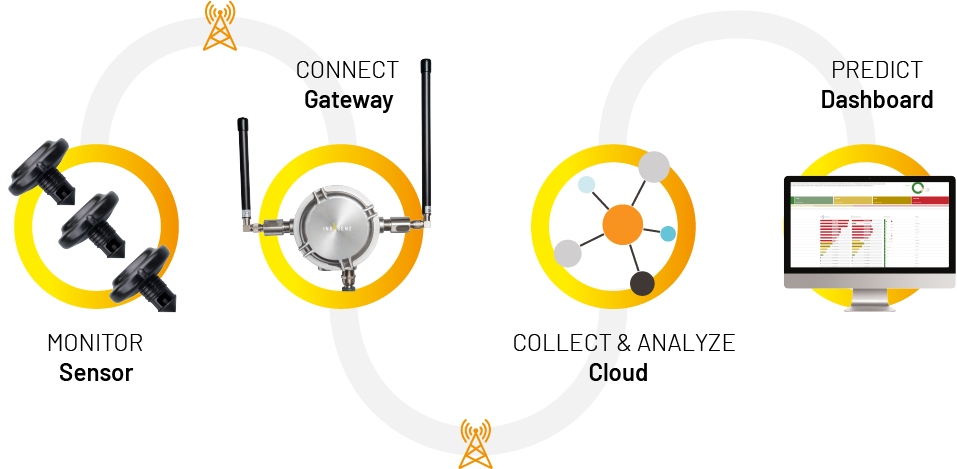

INVENIO RH SERIES SENSORS

We utilize in-house manufactured EX certified sensors to monitor temperature and humidity on insulated equipment and pipes, fitting flexibly in any location.

INVENIO GW-1 GATEWAY

EX certified gateway units wirelessly gather and transmit sensor data through either 4G, Ethernet, or WiFi protocols, effectively centralizing corrosion data management.

INVENIO CLOUD

Utilizing advanced analytics, continuous monitoring, and historical data, a predictive program for CUI asset integrity is essential for extending asset life.

CUI MONITORING DASHBOARD

Web-based dashboard for control, analysis, and monitoring. Integrates with existing management systems and major industrial IoT platforms. Data access via APIs.

Indusenz INVENIO RH Sensor

In-house manufactured EX-certified sensors are installed on relevant production equipment/piping to monitor insulation relative humidity and temperature conditions. The flexible sensors can be retrofitted in any location without removing insulation. The RH sensor comes in two versions:

- RH-1CX optimized for even longer battery lifetime

- RH-2 utilizing existing LoRaWAN networks

Gateways

INVENIO Cloud and Dashboard

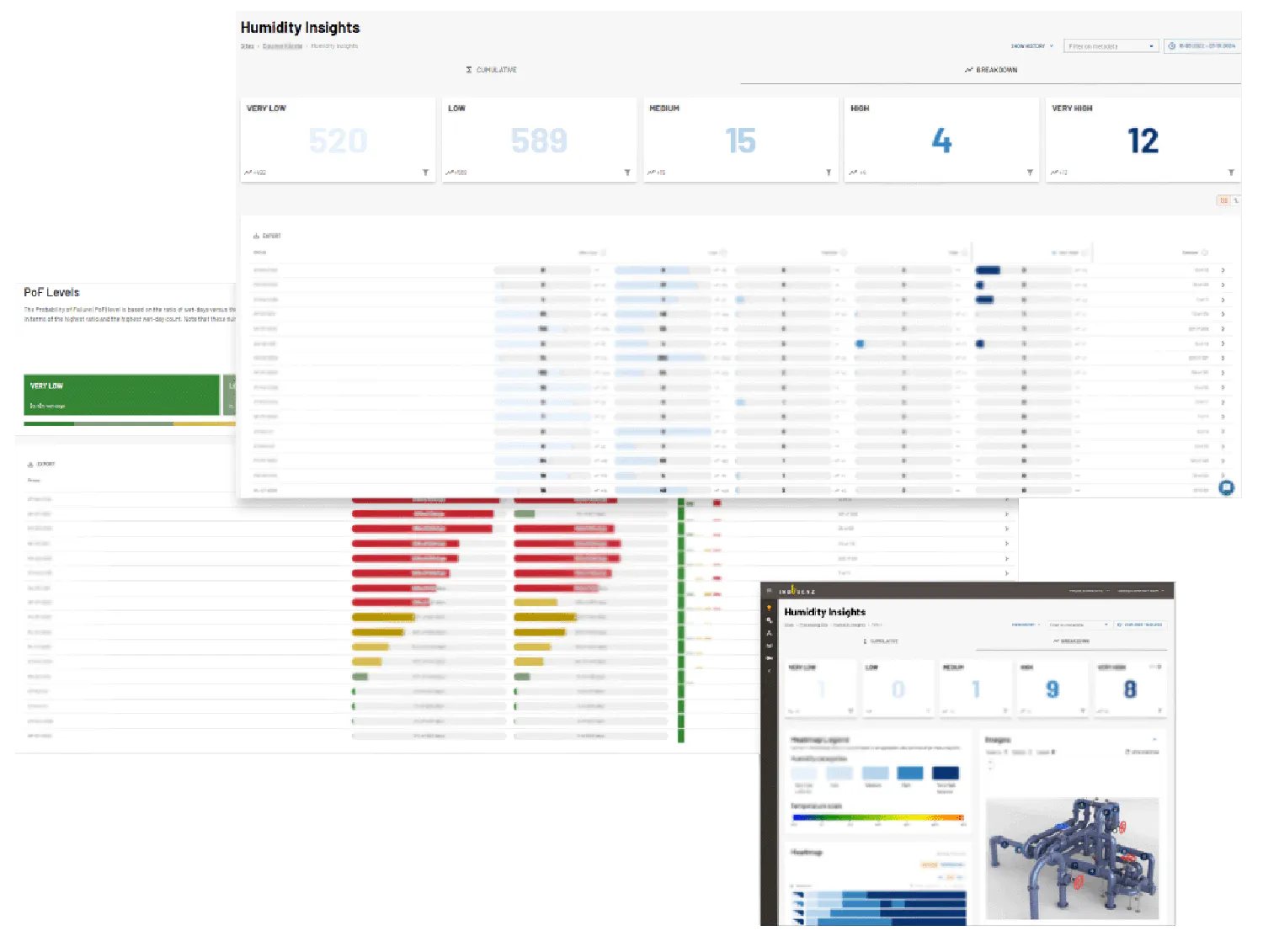

- The system includes a CUI monitoring dashboard, which enables a higher-level visualization of the current and historical water-wetting state. This means that the user has an overview of the state of the entire asset, with the possibility to highlight best/worst case areas and to drill down into these areas to see which parts of the respective areas are affected and for how long. The user can focus more on the risk domain, and less on interpreting raw data from the sensors.

- Top-down approach: A top-level overview provides insights to overall conditions as well as the option to drill further down into details, with customizable metadata fields and filtering supporting customer-specific needs. The system outputs the Probability of Failure related to the water-wetting barrier of the instrumented equipment.

- Federated authentication: The system can be set up with end-user login through the customer’s own Identity provider via OpenID Connect (OIDC).

- API: The system offers HTTP API access to data with industry-standard OAuth 2.0 authorization. Indusenz provides API documentation conforming to the OpenAPI v3.0 specification, along with integration guides for developers.

Benefits

Minimize HSE Risk

Improved detection leads to reduced risk of catastrophic failure. Less time spent inspecting means less exposure to HSE risk.

Retrofit Installation

Easily scalable installation and monitoring are available for both rehabilitation and retrofit projects.

Corrosion-Aware Maintenance

Enhances confidence in workmanship. Lowers repair needs, CO2 emissions, and operational expenses.

Data-driven RBI

Simple web-based dashboard for data visualization and customer system interface.

Predictive maintenance

Extend intervals by knowing where the insulation is dry.

Optimized Crew

Safe, Reliable, and Efficient.